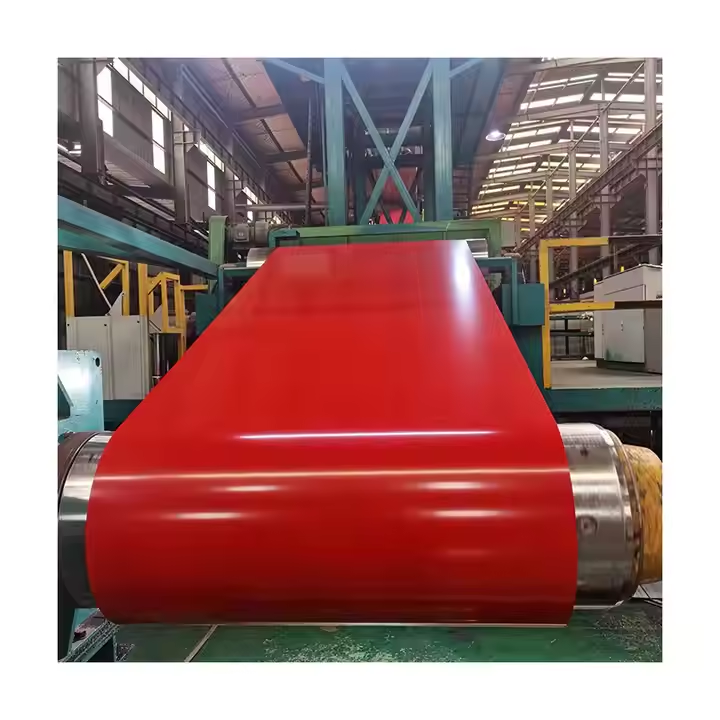

Color-coated steel coils are building materials made by coating an organic paint onto a metal substrate and then baking and curing it. The substrate is typically made of cold-rolled steel, galvanized steel, aluminum, or aluminized zinc sheet. A continuous roll coating process forms multiple layers, giving the coils rich colors, good corrosion resistance, and weather resistance.Its main applications cover multiple fields:

- Construction Industry: Widely used in roofing, wall panels, partition systems, aluminum composite panels, ceilings, and billboards in industrial plants, commercial buildings, and residences, providing lightweight, easy-to-install, and aesthetically pleasing solutions.

- Home Appliances and Electronics: Used as a material for the casings of home appliances such as refrigerators and washing machines, or for the enclosures of electronic products, emphasizing surface smoothness and wear resistance.

- Industrial Facilities: Used in ventilation ducts, warehouse structures, garage doors, partition walls, etc., providing corrosion protection, heat insulation, and structural support.

- Transportation and Packaging: Some models are used in automotive interiors, vehicle panels, or packaging materials, utilizing their lightweight and processability.

When making a selection, the coating type and substrate thickness should be comprehensively considered based on environmental conditions (such as the need for enhanced corrosion-resistant coatings in coastal areas with high salt spray) and specific requirements (such as color durability and mechanical strength).

Color-coated steel coils are building materials made by coating an organic paint onto a metal substrate and then baking and curing it. The substrate is typically made of cold-rolled steel, galvanized steel, aluminum, or aluminized zinc sheet. A continuous roll coating process forms multiple layers, giving the coils rich colors, good corrosion resistance, and weather resistance.

Its main applications cover multiple fields:

- Construction Industry: Widely used in roofing, wall panels, partition systems, aluminum composite panels, ceilings, and billboards in industrial plants, commercial buildings, and residences, providing lightweight, easy-to-install, and aesthetically pleasing solutions.

- Home Appliances and Electronics: Used as a material for the casings of home appliances such as refrigerators and washing machines, or for the enclosures of electronic products, emphasizing surface smoothness and wear resistance.

- Industrial Facilities: Used in ventilation ducts, warehouse structures, garage doors, partition walls, etc., providing corrosion protection, heat insulation, and structural support.

- Transportation and Packaging: Some models are used in automotive interiors, vehicle panels, or packaging materials, utilizing their lightweight and processability.

When making a selection, the coating type and substrate thickness should be comprehensively considered based on environmental conditions (such as the need for enhanced corrosion-resistant coatings in coastal areas with high salt spray) and specific requirements (such as color durability and mechanical strength).